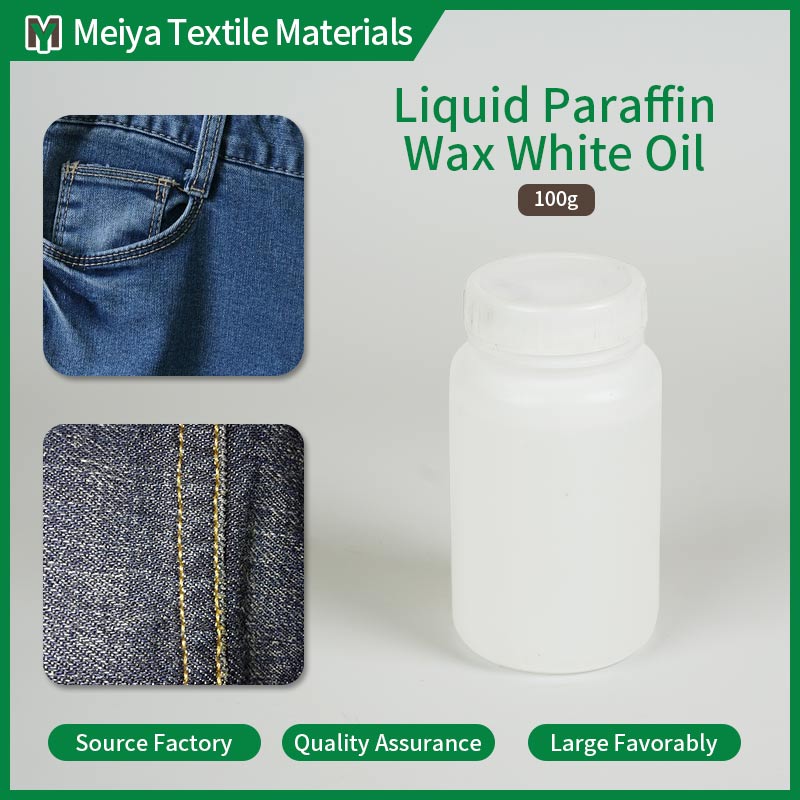

Industrial Grade Light Paraffin Oil

Please click the button below to contact us.

Introduction:Light Paraffin Oil is a kind of odorless and tasteless light liquid paraffin obtained from petroleum distillation, which is a kind of mineral oil. It has good chemical stability, is not easy to react chemically with other substances, has relatively stable properties, and can basically maintain its own characteristics at normal temperature and pressure.

Product Description

Light Paraffin Oil is a kind of odorless and tasteless light liquid paraffin obtained from petroleum distillation, which is a kind of mineral oil. It has good chemical stability, is not easy to react chemically with other substances, has relatively stable properties, and can basically maintain its own characteristics at normal temperature and pressure.

Light Paraffin Oil Features

High purity of ingredients: The main component of Light Paraffin Oil is a mixture of various alkanes, the content is usually between 95% and 99%, and the impurity content is extremely low, such as sulfur content is generally less than 0.1%, nitrogen content is less than 0.01%, which makes it produce less pollutants when burned, and is more conducive to use with other materials without adverse reactions.

Viscosity characteristics: Its kinematic viscosity is generally between 1.5 and 6mm²/s at 40℃. The low viscosity property allows it to quickly penetrate into the fiber gaps of textile materials and evenly coat the fabrics. For example, in the soft finishing process of some light fabrics such as cotton gauze, it can be quickly distributed without making the fabric feel heavy.

Chemical stability data: When stored at room temperature, even if it is placed for several years, its composition will not change significantly. Through accelerated aging tests (such as continuous placement at 80℃ for 100 hours), its main performance indicators such as viscosity and chemical composition change rate are less than 5%, ensuring reliable performance in textile production and subsequent use.

Flash point performance: The flash point is usually between 60-70℃. This flash point range not only ensures that it is relatively safe when used under general textile processing temperature environment (most textile heat setting process temperatures are around 100-200℃), but also satisfies its lubrication and softening functions in some low-temperature processing links to a certain extent. It will not cause flammability risks due to too low flash point, nor will it affect its fluidity and other performances at normal processing temperature due to flash point.

Density characteristics: The density is generally between 0.83-0.86g/cm³ (at 20℃). Such a density allows it to be well mixed with various textile auxiliaries, dyes, etc. In the printing, dyeing, finishing and other processes in textile production, it can be evenly integrated with these substances to form a stable mixed system to ensure the uniformity of fabric treatment.

Acid value index: The acid value is extremely low, usually less than 0.1mgKOH/g, which means that it is almost neutral and will not corrode fibers and other components in textile materials. When it comes into contact with various fiber materials (such as cotton, linen, silk, wool, etc.), it will not cause fiber performance degradation due to acidity or alkalinity problems, such as reduced strength of cotton fibers and damaged silk luster.

Application of Light Paraffin Oil

In the textile printing and dyeing process, when printing and dyeing cotton cloth, Liquid Light Paraffin Oil can be added to the printing and dyeing auxiliaries, and the amount generally accounts for 3% - 5% of the total amount of auxiliaries. It can effectively improve the uniformity of dye adsorption on cotton fibers, make the color of the dyed cotton cloth more full and uniform, reduce color difference problems, and improve the appearance quality of the product. It can form a uniform liquid film on the fiber surface, allowing the dye molecules to adhere to the fiber more orderly and optimize the dyeing effect.

In the production of velvet fabrics such as towels, it is used as a softening finishing agent. The amount of addition is about 2% - 4% of the fabric weight. After impregnation, drying and other processes, the softness of the towel can be significantly improved, the feel changes from relatively rough to delicate and soft, the friction coefficient is reduced by about 30% - 40%, and the comfort of use is improved. After multiple washings, it can still maintain a good soft effect, because it can form a lasting lubricating film on the fiber surface.

In the yarn production stage, it can be used as one of the components of spinning oil, accounting for 10% -15% of the total oil. It can effectively reduce the friction coefficient between fibers in the spinning process of yarn, usually by 20% - 30%, reduce the yarn breakage rate, improve the spinning efficiency and the quality of yarn forming, make the yarn smoother and more uniform, and help the smooth progress of subsequent weaving processes, especially suitable for cotton and wool spinning yarn production.

For the production of leather and textile composite materials, such as automotive seat fabrics (leather and fabric composites). During the compounding process, Liquid Light Paraffin Oil can be used as an interface lubricant, and the addition amount is between 1% and 2% of the total composite material. It can improve the fit between leather and textiles, make the combination of the two more firm and smooth, reduce gaps and wrinkles, improve the appearance and performance of the composite material, enhance its wear resistance, and extend its service life.

In the production of non-woven fabrics, especially the application of melt-blown non-woven fabrics in the production of protective equipment such as masks, Liquid Light Paraffin Oil can be added to the melt-blown material, and the addition amount is about 0.3% - 0.8% of the weight of the melt-blown material. It can improve the rheological properties of the melt-blown material, make the melt-blown process smoother, and make the fiber fineness more uniform. The filtration efficiency of the produced non-woven fabric can be increased by about 5% - 10%, while maintaining good air permeability, which is of great significance to improving the protective performance and wearing comfort of protective equipment.

Light Paraffin Oil Maintenance:

Storage temperature control is critical. Liquid Light Paraffin Oil should be stored in an environment of 5 - 35℃. Because the temperature is too high (over 40℃), its volatilization rate will accelerate, and 2% - 3% volatilization loss may occur every month, and it may also affect the stability of its ingredients; if the temperature is too low (below 0℃), it may cause crystallization. Although crystallization is reversible, it will affect the fluidity and uniformity during normal use. It needs to be reheated and stirred to restore it to liquid state, which increases the trouble of use.

For the selection and management of storage containers, dark glass bottles or stainless steel containers with good sealing should be used. If plastic containers are used, some plastic components may react slowly with petroleum jelly, resulting in a decrease in the purity of the oil, and an increase in impurity content of 0.5% - 1% per month. And the sealing of the container should be checked regularly, at least once a quarter, and the seal should be replaced in time if the sealing is poor to prevent moisture and impurities in the air from entering and affecting the quality of petroleum jelly.

Storage away from light is a necessary maintenance method. Liquid Light Paraffin Oil may undergo photochemical reactions under light conditions, especially ultraviolet rays, causing the alkane components in it to gradually undergo oxidation, cracking and other changes. According to tests, long-term exposure to sunlight (more than 8 hours of light per day) may increase its viscosity by 5% - 8% per month, and its color may gradually turn yellow, affecting its use in applications such as textiles that require color, so it is best to store it in a light-proof warehouse or cabinet.

There are also particularities in the use and maintenance during use. The tools used should be kept clean and dry to avoid the introduction of impurities such as moisture and dust left on the tools into the vaseline oil. The container should be sealed in time after each use to reduce the contact time with the air, prevent it from absorbing moisture in the air (water absorption rate is generally less than 0.05%/day) and deteriorating, and also avoid volatile losses. If it is found that the tools used to take impurities accidentally bring in, they should be filtered in time, generally using a 1μm precision filter to ensure the purity of the vaseline oil.

For inventory management, the first-in-first-out principle should be followed. Since vaseline oil may have slight performance changes after long-term storage, even under good storage conditions, its viscosity may fluctuate by 1% - 2% each year, and its density may change by 0.001 - 0.002g/cm³. Therefore, it is necessary to arrange inventory reasonably to avoid long-term backlogs, try to ensure that the inventory is turned over once every 6 months, and ensure that the vaseline oil with relatively stable performance is used to meet the requirements of material performance stability in textile production and other industries.

Maintenance during transportation is equally important. Avoid severe vibration and collision during transportation, as this may cause vaseline oil to foam in the container. Although the foam will gradually dissipate, it may cause the local concentration of certain components in the oil to change during the dissipation process, affecting its uniformity. The transport vehicle should maintain stable driving, and be handled with care during loading and unloading. At the same time, rain and sun protection measures should be taken to prevent the container from being damaged or the vaseline oil from being adversely affected by external environmental factors, and ensure that its quality is not damaged during transportation.

Light Paraffin Oil FAQ

What are the primary uses of Light Paraffin Oil?

Answer: Light Paraffin Oil is used in the textile industry for waxing threads and fabrics, in candle manufacturing, as a coating in the paper and food packaging industries, as an antioxidant in rubber production, and as a moisture barrier in woodworking and cosmetics.

Is Light Paraffin Oil safe for use in food-related applications?

Answer: Yes, Light Paraffin Oil is safe for use in food-related applications, such as coating food packaging materials and cheese. It is designed to be non-toxic and safe for contact with food products.

Is Light Paraffin Oil biodegradable?

Answer: Light Paraffin Oil is not biodegradable as it is a petroleum-based product. Proper disposal and recycling methods should be followed to minimize environmental impact.

Is Light Paraffin Oil flammable?

Answer: Yes, Light Paraffin Oil is flammable. It should be stored and handled with care, away from open flames and other sources of ignition.