Liquid Paraffin Mineral Oil

Please click the button below to contact us.

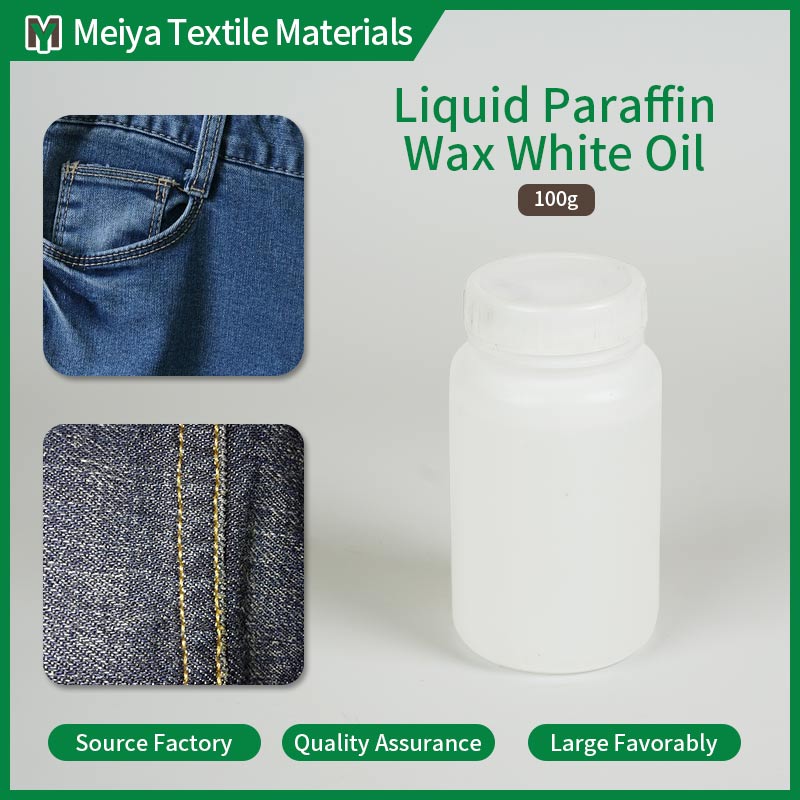

Introduction:Liquid Paraffin Mineral Oil is a highly refined mineral oil, mainly extracted from petroleum and deeply processed. It is a colorless, odorless, transparent oily liquid, whose main components are saturated hydrocarbons, free of harmful substances such as aromatic hydrocarbons and sulfur, and meets many international food safety and health standards.

Product Description

Liquid Paraffin Mineral Oil is a highly refined mineral oil, mainly extracted from petroleum and deeply processed. It is a colorless, odorless, transparent oily liquid, whose main components are saturated hydrocarbons, free of harmful substances such as aromatic hydrocarbons and sulfur, and meets many international food safety and health standards. This oil has a low viscosity, is easy to apply and disperse, and can form a uniform protective film on the surface of various materials.

Liquid Paraffin Mineral Oil Features:

Low viscosity and high fluidity: Liquid Paraffin Mineral Oil usually has a viscosity of 30 - 100 cSt (at 40°C). This means that it has good fluidity and can easily spread between the various parts of textile machinery. This low viscosity property enables it to quickly penetrate into the fabric fibers and evenly cover the fiber surface, thereby effectively reducing the friction between the fibers and improving the softness and smoothness of the fabric. For example, during the padding process of the fabric, the low-viscosity oil can be quickly and evenly distributed on the entire fabric surface, ensuring that each fiber is fully lubricated and protected. In addition, low viscosity also makes it easier for operators to perform operations such as coating and spraying, thereby improving production efficiency.

High flash point and safety: Its flash point is generally higher than 200°C. This makes it safer during the textile production process. In high-temperature environments, such as heat setting and drying of fabrics, the high flash point ensures that the oil will not easily evaporate or burn, reducing the risk of fire. For example, in a high-temperature setting machine, the oil can remain stable even in an environment above 200°C and will not produce flammable volatile gases. At the same time, the high flash point also means that the oil can remain stable at high temperatures and will not decompose to produce harmful substances, thereby extending the service life of equipment and fabrics and reducing production costs.

Low Pour Point and Low Temperature Fluidity: The pour point is usually below -30℃. It ensures its fluidity in low temperature environments. Under cold storage and transportation conditions, Low Pour Point's Liquid Paraffin Mineral Oil will not solidify or become too viscous, making it easy to use at any time. For example, in outdoor warehouses in northern winter, the oil can maintain good fluidity even at a low temperature of -20℃, and operators can use it directly without heating it. In some low-temperature workshops or winter production in textile factories, this feature ensures that the oil can function normally and will not affect the lubrication of equipment and the treatment of fabrics due to low temperatures.

High Density and Good Coverage: The density is about 0.85 - 0.90 g/cm³ (at 20℃). This gives it good covering ability. A dense oil film is formed on the surface of the fabric, which effectively isolates moisture, oxygen and pollutants in the air, thereby preventing the fabric from getting damp, oxidized and contaminated with dust. For example, in the finishing process of the fabric, the high-density oil film can fit tightly on the surface of the fabric fiber to form an effective protective barrier. At the same time, the high-density oil film can enhance the fabric's resistance to wear, reduce fiber breakage and fuzzing, and improve the appearance quality and durability of the fabric.

Low acid value and chemical stability: The acid value is generally lower than 0.1 mgKOH/g. This shows that its chemical properties are mild and will not corrode fabric fibers and textile equipment. In the textile processing process, fabric fibers and metal parts of equipment are easily corroded by acidic substances, and Liquid Paraffin Mineral Oil with a low acid value can avoid this corrosion risk. For example, in the printing and dyeing process, the oil will not react with the chemical components in the dye, nor will it corrode the metal parts of the printing and dyeing equipment. It is well compatible with various fibers (such as cotton, linen, silk, wool, chemical fiber, etc.) and equipment materials (such as metal, rubber, plastic, etc.), ensuring the smooth progress of the production process.

Low iodine value and antioxidant properties: The iodine value is usually between 5 - 10 gI/100g. This indicates that it has an extremely low content of unsaturated bonds and has good antioxidant stability. In textile production, long-term exposure to light and oxygen can cause oil products to oxidize and deteriorate, producing odors and harmful substances. Low Iodine Value Liquid Paraffin Mineral Oil has strong antioxidant capacity and can maintain stable performance during long-term use. For example, during the storage and transportation of fabrics, the oil will not deteriorate due to long-term oxidation, thereby reducing the impact of oxidation products on fabrics and equipment, and maintaining the cleanliness and safety of the production environment.

Good compatibility and versatility: Liquid Paraffin Mineral Oil is compatible with a variety of materials. It is not only compatible with various natural and synthetic fibers, but also can be mixed with auxiliaries, dyes, coatings and other substances commonly used in textile processing without stratification or precipitation. For example, in the softening finishing agent of fabrics, it can be mixed with other softeners such as silicone oil in any proportion to form a uniform mixture and work together. This good compatibility makes it widely applicable in textile production and can meet the needs of different processes and products.

Low volatility and durability: Its volatility is extremely low and it hardly evaporates at room temperature. This allows it to maintain its lubricating and protective effects on fabrics for a long time. For example, during the storage and sales of fabrics, the oil will not be reduced due to volatilization, and the fabric always maintains a soft and smooth feel. At the same time, low volatility also reduces the loss of oil in the production process, reduces production costs, and reduces the emission of volatile organic compounds (VOC), which is beneficial to environmental protection.

Environmental protection and degradability: Liquid Paraffin Mineral Oil meets many international environmental standards, such as REACH, FDA, etc. It is environmentally friendly and will not cause pollution to soil, water bodies, etc. Although it is a petroleum product, it has a certain degree of degradability because its components are mainly saturated hydrocarbons. In the natural environment, after a long time, it can be decomposed into carbon dioxide and water by microorganisms, reducing the long-term impact on the environment. For example, when wastewater containing a small amount of oil is discharged into the sewage treatment system, the oil in it can be gradually decomposed by microorganisms during the sewage treatment process, thereby reducing the pollution to the water environment.

Low toxicity and safety: Liquid Paraffin Mineral Oil has extremely low toxicity and is non-irritating to the skin and respiratory tract. In the textile production process, operators will not cause allergic or poisoning reactions even if they are exposed to it for a long time. For example, in the fabric finishing workshop, when workers use oil for padding or spraying operations, as long as they follow the correct operating procedures, there is no need to worry about causing harm to the body. At the same time, it also meets food grade standards and can be used in the production of food packaging materials to ensure that it will not cause contamination to food during food processing and packaging.

Liquid Paraffin Mineral Oil Application:

Textile production: In the textile raw material stage, Liquid Paraffin Mineral Oil can be used for the pretreatment of natural fibers such as cotton and wool. By soaking or spraying, a protective film is formed on the fiber surface to prevent the fiber from being damaged by friction during storage and transportation, and improve the spinnability of the fiber. In the spinning process, it can lubricate the rollers, spindles and other parts of the spinning machine, reduce the friction between the fiber and the metal parts, reduce the breakage rate, and improve the strength and uniformity of the yarn. In the weaving process, the warp and weft shafts of the loom are lubricated to ensure the smooth weaving process, reduce the wear of the sley, shuttle and other parts, and improve the density and appearance quality of the fabric. In the printing and dyeing stage, adding it to the printing and dyeing bath helps to evenly disperse the dyes and auxiliaries, making the fabric color more uniform and more colorful. In the finishing process, as a softener and hand finishing agent, it is applied to the fabric by padding, dipping or spraying, making the fabric soft, smooth and plump, while enhancing the wrinkle resistance and drape of the fabric.

Food packaging: Liquid Paraffin Mineral Oil meets food safety standards and can be used in the production of food packaging materials. In the field of paper packaging, it is used to coat the surface of paper, such as food packaging paper, baking paper, etc., to form a waterproof and oil-proof protective layer to prevent grease and moisture in food from penetrating into the paper and extend the shelf life of food. In plastic packaging, as a plastic additive, it improves the flexibility and transparency of plastic film, while preventing the migration of plasticizers in plastics, ensuring the safety and stability of food packaging. In metal packaging, the inner wall of food cans is coated to prevent corrosion and contamination caused by direct contact between food and metal, and to ensure the quality and taste of food.

Pharmaceutical industry: Liquid Paraffin Mineral Oil has many uses in the pharmaceutical process. In pharmaceutical preparations, it is used as a lubricant in the production of tablets and capsules to prevent drug powder from adhering to the die and capsule shell, ensuring the molding quality of the drug. In drug storage, drug packaging containers (such as glass bottles, plastic bottles, etc.) are coated to prevent chemical reactions between drugs and packaging materials, while reducing friction and damage to drugs during the packaging process. In the maintenance of pharmaceutical equipment, it is used to lubricate and maintain the moving parts of pharmaceutical machinery such as bearings and gears to prevent rust and wear of the equipment, ensure the continuity and stability of the pharmaceutical process, and avoid the contamination of drugs by lubricants.

Leather manufacturing: In the leather tanning process, Liquid Paraffin Mineral Oil can be used as a filler and lubricant for leather. It can penetrate into the leather fibers and fill the gaps between the fibers, making the leather fuller and softer. At the same time, a protective film is formed on the surface of the leather to prevent the leather from getting damp, moldy and cracked, and extend the service life of the leather. In the leather finishing stage, it is mixed with leather coating to improve the leveling and adhesion of the coating, making the leather surface smoother, more delicate and more glossy. In the maintenance of leather finished products, it is used for surface care of leather products (such as shoes, bags, furniture, etc.), by wiping or spraying, to restore the softness and gloss of the leather and repair minor scratches and wear.

Cosmetic production: Liquid Paraffin Mineral Oil is a commonly used matrix raw material in cosmetics. In skin care products, such as lotions, face creams, hand creams, etc., as moisturizers and nourishing agents, they can form a breathable oil film on the skin surface, lock in skin moisture, prevent water evaporation, and provide moisture and nutrition to the skin. In cosmetics, such as lipsticks, eye shadows, foundations, etc., as film formers and dispersants, they make cosmetics have good spreadability and adhesion, while improving the texture and stability of the products. In personal care products, such as shampoos, conditioners, shower gels, etc., as conditioners and softeners, they make hair and skin softer and smoother, and reduce static electricity.

Agricultural field: Liquid Paraffin Mineral Oil can be used in agriculture for crop protection and pest control. As a protective agent for plant leaves, it forms a thin oil film on the surface of crop leaves, which can reduce water evaporation, improve the drought resistance of crops, and prevent the invasion of pathogens and pests. In terms of pest control, spraying a solution containing Liquid Paraffin Mineral Oil can block the pests' breathing holes, suffocating them to death, which is a relatively environmentally friendly biological control method. In addition, it can also be used for the lubrication and maintenance of agricultural machinery to prevent mechanical parts from rusting and wearing in the humid and dusty farmland environment, ensuring the smooth progress of agricultural production.

Liquid Paraffin Mineral Oil Maintenance:

Storage temperature control: Liquid Paraffin Mineral Oil should be stored in an environment with a temperature of 5 - 35℃. Excessively high temperatures will accelerate the volatilization and oxidation of the oil, resulting in a decrease in its performance. For example, when the temperature exceeds 40℃, the volatilization rate of the oil will be significantly accelerated, and the daily loss may reach 0.5% - 1%. Too low a temperature will increase the viscosity of the oil, deteriorate its fluidity, and make it difficult to use. In winter, if the storage temperature is below 0℃, the oil may solidify and need to be heated to 10 - 15℃ before it can be used normally. In order to accurately control the storage temperature, it is recommended to install temperature control equipment such as air conditioning, heating, etc. in the storage warehouse, and equip it with a thermometer for real-time monitoring to ensure that the temperature is always within the appropriate range.

Container selection and sealing: Liquid Paraffin Mineral Oil should be stored in stainless steel, glass or food-grade plastic containers. These materials have good chemical stability and will not react with the oil. The sealing of the container is crucial, and a double-layer sealing structure is required. The first layer is a tight bottle cap or can cover, and the second layer can be sealed with sealing tape or sealing gasket. For example, for large oil storage tanks, flange connections can be used and sealed with oil-resistant rubber gaskets; for small bottled oils, use screw-on bottle caps with linings. Check the sealing of the container regularly. If the sealing tape is found to be aging or the bottle cap is loose, it should be replaced or resealed in time. Be sure to seal the cap immediately after each use to avoid the oil being exposed to the air for a long time.

Moisture and Waterproof: Make sure the relative humidity of the storage environment is less than 70%, because Liquid Paraffin Mineral Oil will emulsify when it comes into contact with water, affecting its performance. The storage warehouse should be kept dry and ventilated, and moisture-proof mats such as plastic film or waterproof floor tiles can be laid on the ground. At the same time, avoid storing oil near water sources or places where there is a risk of water leakage, such as windows, under the roof, etc. If the oil is accidentally exposed to water, the contaminated part should be separated immediately. For large amounts of oil, a separatory funnel can be used for dehydration; for small amounts of oil, it can be left for a period of time and the water can be removed after natural stratification. During use, operators should wear dry gloves to prevent moisture from contacting the oil.

Dust and pollution prevention: The storage warehouse should be cleaned regularly to keep the air clean. Air filters can be installed to prevent dust from entering. At the same time, avoid mixing oil with other pollutants such as chemical reagents and paints. During transportation and use, operators should wear clean work clothes to avoid bringing dust and impurities into the oil. If the oil is slightly contaminated, it can be filtered with a fine filter (such as 100-200 mesh) and continued to be used; if the contamination is serious (such as mixing with a large amount of chemicals or impurities), the contaminated oil needs to be specially purified or discarded. After each use, clean the oil stains and dust around the container in time to keep the surface of the container clean.

Regular inspection and record: Check the appearance and odor of Liquid Paraffin Mineral Oil at least once a month. Under normal circumstances, the oil should be colorless, transparent and odorless. If the oil is found to be darker in color, turbid or has a pungent odor, it may be caused by oxidation or contamination. Samples should be taken immediately and sent to a professional laboratory for testing. Key indicators such as viscosity and acid value should be tested once a quarter. Viscometers and acid-base titration methods can be used. At the same time, detailed storage and use records should be established, including information such as purchase date, usage, remaining amount, and inspection results. Through these records, the trend of oil quality changes can be discovered in time, and measures can be taken in advance, such as adjusting storage conditions or replacing oil.

Safety and emergency treatment: Although Liquid Paraffin Mineral Oil itself is low in toxicity, safety should still be paid attention to during storage and use. Storage warehouses should be equipped with fire extinguishers (such as carbon dioxide fire extinguishers, dry powder fire extinguishers, etc.) in case of fire. Operators should wear goggles and masks when using to prevent oil from splashing into the eyes or inhaling into the respiratory tract. If it accidentally comes into contact with the skin, it should be rinsed immediately with plenty of clean water; if it splashes into the eyes, rinse with running water for at least 15 minutes and seek medical attention in time. Develop an emergency response plan. If a large amount of oil leaks, people should be evacuated immediately, and sand or special adsorbent materials should be used for containment and adsorption. Then the contaminated materials should be properly handled to avoid pollution to the environment.

Liquid Paraffin Mineral Oil FAQs:

1. What are the benefits of Liquid Paraffin Mineral Oil in the textile manufacturing processes?

The efficiency of the textile manufacturing processes is greatly enhanced with the use of Liquid Paraffin Mineral Oil. Liquid Paraffin Mineral Oil, when employed in spinning, weaving, and finishing, is a suitable lubricant that minimizes surface friction between elements of machinery and fibers. Our Liquid Paraffin Mineral Oil extends the life and enhances the quality of the textile products allowing textile producers’ production rates to be high and interruptions to be minimal.

2. Can your Liquid Paraffin Mineral Oil be used with all kinds of textile machines?

Yes, our Liquid Paraffin Mineral Oil is multipurpose, and can be applied in different types of textile machines. Whether it is a high-speed spinning machine, a weaving loom, or tacks and finishing equipment, our Liquid Paraffin Mineral Oill gives the most effective lubrication and protection. It reduces the friction, enhances corrosion resistance, and increases the durability of the vital wear and strain components.

3. How can I be sure of the quality and purity of your Liquid Paraffin Mineral Oil?

We are a dependable Liquid Paraffin Mineral Oil producer and supplier. The Liquid Paraffin Mineral Oil we sell is subjected to extensive research and has the required industry measures. It goes through the best processes to ensure that it is of high purity and low aromatic content while being stable. We examine every batch for uniformity and upon clients’ request, we issue certificates of analysis as a proof of the acceptable quality of our products.

4. What are the appropriate storage conditions for Liquid Paraffin Mineral Oil?

Proper storage techniques are quite essential in guaranteeing the desired quality components of Liquid Paraffin Mineral Oil. The product must be kept in a cool and dry environment shielded from sunlight, heat and open flames. The practice of keeping the oil in tightly sealed containers is advised to avoid the presence of contaminants and moisture.

5. What precautions should be taken when using Liquid Paraffin Mineral Oil?

Our Liquid Paraffin Mineral Oil is one of the finest refined Liquid Paraffin Mineral Oil available but this Liquid Paraffin Mineral Oil contains a number of minerals so it cannot be used without care. Protective gloves and goggles should be used in order to prevent any skin or eye exposure. Large use of this oil should be conducted in well-ventilated areas to avoid overexposure to it.